Watch the Jin Sheu Custom Process: Create Your Metal Gifts

Jin Sheu Online Factory Tour

Jin Sheu is the largest metal pin badge, coin, and medal manufacturer in the world. We surpass our competitors not only by factory scale, and advanced equipment but also by the sheer volume that we are able to produce every day. We firmly believe that a factory tour is a great way to learn about a company’s products and manufacturing facility. Consequently, Jin Sheu duly welcomes you to join us on a tour of our metal factory in Dongguang, China where our metal products are manufactured. In these videos, we will reveal the manufacturing processes such as die stamping, die casting, and various printing methods in which Jin Sheu's factory specializes.

Through these videos, we wish to share with you the crafting experts behind the equipment as well as the production lines and the manufacturing processes. We take you behind the scenes to the work surroundings and meet the people who are passionate about creating the perfect customized metal products and providing good quality outcomes for our clients.

DIE STAMPING

DIE STAMPING

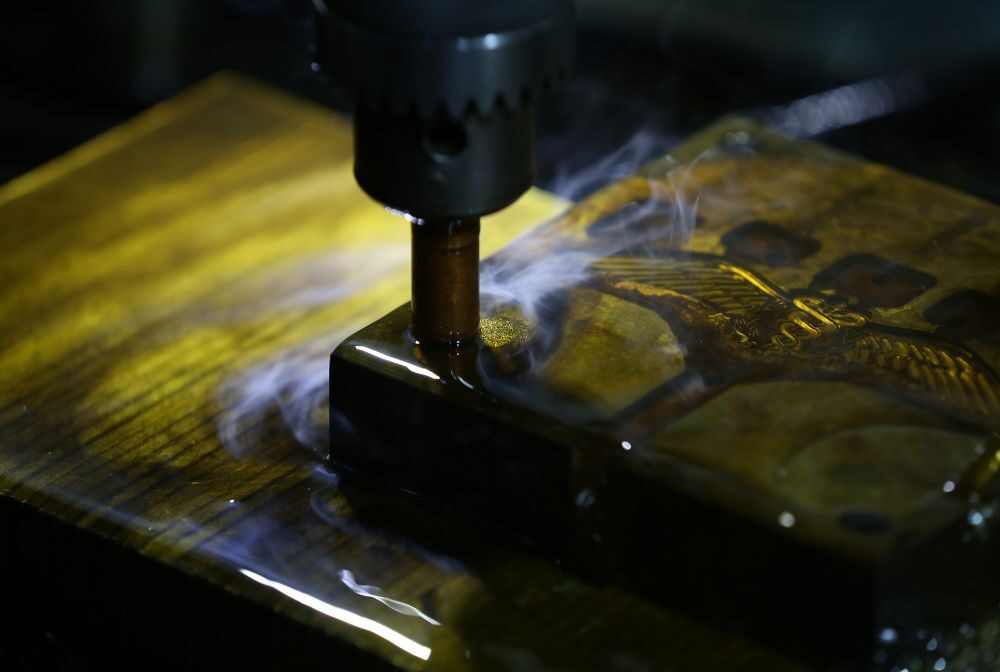

Die stamping is one of the most effective methods of producing metal components that has been used for many years. In our metal factory, Dongguang, China, die-stamping is often utilized when producing coins, pins, badges, medals, etc. The first step of the entire process is to have an inverse image of a custom design carved into a metal die. The die is then loaded into a machine to be ready for the second step. When thousands of tons of pressure strike down, it creates a deep impression of the design on strips of metal or individual metal pieces depending on the size and thickness of the base metal.

Finally, a cut-to-shape mold is created separately to shear off the excess metal around the design. The metal emblem has taken its basic form at this stage and is about to be transformed into something further with the help of our craftsmanship. Our metal factory is equipped with 50+ advanced stamping machines including 3 jumbo-sized hydraulic stamping presses. Most of the stamping machines are operated manually. A few of them are automatic stamping machines which are suitable for large quantity orders. The three jumbo-sized stamping presses are known as the largest machines in the emblem business and it is employed when the emblem size is over 3” (76cm). Usually, the thickness of metal is in proportion to the mold so it can bear tons of high pressure from the stamping press.

DIE CASTING

DIE CASTING

Die casting is a manufacturing process that was developed to produce metal parts in high quantities at a low cost. This process is widely utilized in the lapel pin industry and gained wide popularity for its relatively short production time and its ability for complex details. For fully cubic miniatures, large coins, designs with 3D high relief, intricate details, and quite a few cutouts, die casting is the perfect process for the job. It offers a wide array of shapes and forms which is more economical and efficient than brass. Die Casting is also a wonderful option for designs with mechanical functions such as sliding and spinning badges.

In Jin Sheu, we work with zinc alloy mostly when it comes to die casting process. Zinc alloy has a relatively low melting point which makes it easy to reach the melting point. Once it is heated to molten form, it’s time to inject the liquid into the cavity in the mold that we created for the job. After the metal cools slightly and solidifies, it is removed from the mold and the surface of the metal is often of high quality and therefore requires less post-production process. The excess metal can be easily trimmed off and there’s no extra die required. Zinc alloy provides us with greater flexibility in design and allows us to render more details that would be difficult to do with die stamp process.

PRINTING

PRINTING

As its name suggests, these pins are printed directly on metals. Printed pins are a great option when the designs are complicated and require multiple colors. There’s no need for stamping and filling in enamels, therefore, the production process is faster and more affordable than die-struck or die-cast processes. Printed pins are usually 0.7~0.8mm thick which is thinner and lighter than the other processes so printed pins save on shipping costs as well.

The surface of the printed pins is usually epoxy or lacquer covered to protect the printing from being scratched off. Offset printing, also known as CMYK 4-color process, provides an exact duplicate of what is provided. Gradient colors can be found and colors cannot be separated. The color for screen printing is printed one by one in solid color. Printing can be combined with soft enamel, imitation hard enamel, or real cloisonne and this method is commonly found in lapel pins, keychains, coins, and so on. Applications of printing are versatile and effective with unlimited colors. Try a few combinations and you will be amazed by the results.

POLISHING

METAL POLISHING

Polishing is an important and necessary process for removing sharp edges and burrs from stamping or die casting. It increases the appearance of the metal surface and brings a luster shine to the products. Before the development of automated polishing machines, polishing can only be done by hand which consumes much of the production time. After the purchase of the automated polishing machines, we are able to lower the labor costs and speed up the manufacturing process, which allows us to award the benefits to our customers by offering better costs and better products.

ELECTROPLATING

ELECTROPLATING

Electroplating is an essential part of any design. It changes the surface color of the metals and creates specific color finishes. The plating colors can be easily categorized into shiny and matte finishes. The popular options for shiny finishes are gold, nickel, silver, copper, and black nickel. Matte finish provides a non-reflective surface and is often chosen to show contrast and create intricate eye-catching details. The options are antique gold, silver, bronze, and copper. For some designs, a two-tone finish that utilizes a masking technique is used to create a distinctive look.

While most factories send their products out to other workplaces for electroplating, Jin Sheu built in-plant automated electroplating tanks in 2008 which allows us to closely monitor the quality of our metal products and speed up the production process to better serve our clients.

COLORING

Cloisonné

Cloisonné is an ancient decorative art that requires high skills in coloring, firing, grinding, and polishing. The coloring pigments for cloisonne are derived from mineral powders or fossils which are difficult to obtain. As brass is the only acceptable base metal for cloisonne, the manufacturing costs are quite high compared with imitation hard enamel and soft enamel. The manufacturing process requires meticulous details and lengthy procedures. When Mr. Sheu, the founder of Jin Sheu, accepted his very first job in manufacturing emblems, it was Cloisonné. Therefore, you can say that Cloisonné (hard enamel) is the linchpin of Jin Sheu which is one of the few factories that still does Cloisonné emblems.

Imitation Hard Enamel vs Soft Enamel

The stamping or injection process gives an emblem the initial form, the coloring process is what makes it come to life. Imitation hard enamel and soft enamel are by far the two of the most popular coloring techniques in the emblem making industry.

IHE, short for imitation hard enamel, is also called clois-tech, synthetic cloisonne, or soft cloisonne. The main characteristic of imitation hard enamel is that its colors and metal rims are flat. It is done by filling up the enamel all the way and over the metal rims, then grinding off the excess enamels gradually to a smooth and polished flat presentation.

Soft enamel, on the other hand, is in liquid form before it is baked dry. Unlike imitation hard enamel, the colored areas are recessed. A layer of clear epoxy coating is sometimes added on top of the soft enamel for extra protection and for aesthetic purposes.

UV PRINTING

UV PRINTING

UV printing is definitely a creative application and the hottest new trend in the market. It is energy-efficient, eco-friendly, and can be utilized in nearly all fields practically. The UV ink cures almost instantly, in other words, it is a quick drying printing process that allows for a faster production turnaround. The versatility of UV printing not only brings more creative power to our designers but also enables designers to choose from diversified media to suit their artistic creativity. Check out the videos on UV-printed products and get inspired!

WASTEWATER TREATMENT

WASTEWATER TREATMENT PLANT

A wastewater treatment plant treats industrial wastewater and removes pollutants and toxicants before it is released back into nature. Right after obtaining a license for building an in-house electroplating plant, we begin to set up a wastewater treatment facility that was constructed and supervised according to the local government’s regulations. The wastewater treatment plant is one of the most valuable assets of the entire facility in Dongguang, China. An investment of over fifty thousand US dollars, its establishment demonstrated our determination to protect the environment and fulfill social responsibility. Jin Sheu has been awarded a “Green Label” enterprise in the year of 2008 by the Dongguang government.