Complete Guide to Creating Custom Lapel Pins | Perfect for Beginners

Your design journey made simple—even for first-timers!

Want to create your own custom lapel pin but don’t know where to start?

What file types does the factory need? How thick should the lines be? How many colors can you use? Can you include cutouts in a design?

Don’t worry! this guide walks you through the 6 essential design rules to ensure your first lapel pin design is production-ready and smoothly enters the manufacturing stage.

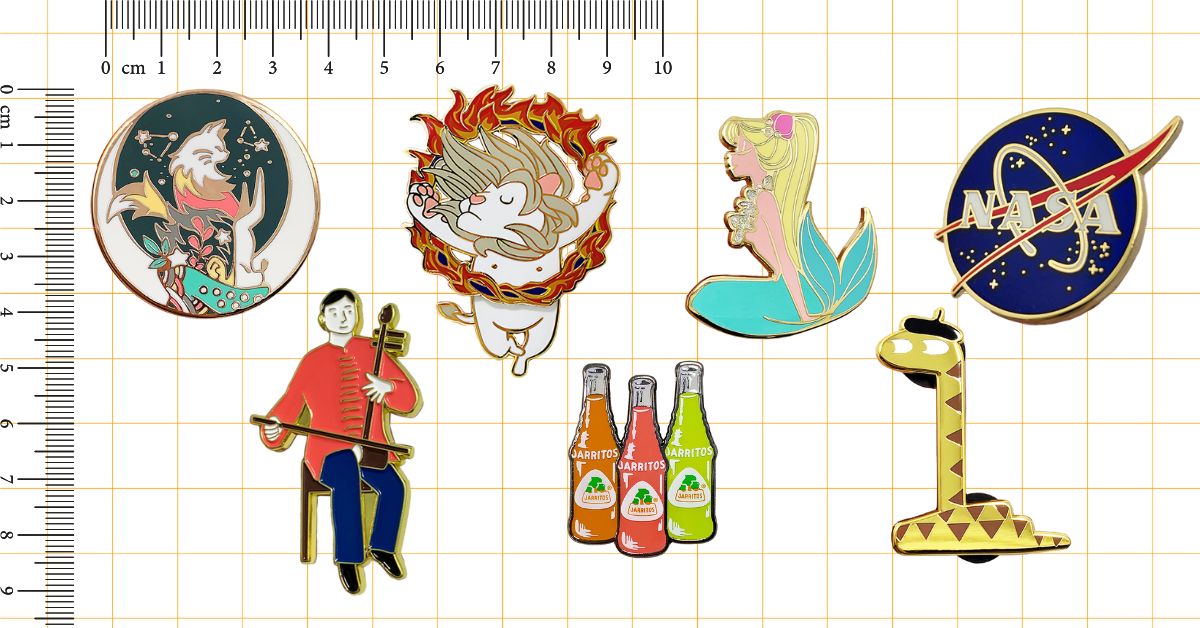

Recommended Lapel Pin Size

Metal pins come in fully customizable shapes and dimensions, but for wearability and aesthetics, the most common size ranges from 2cm to 4cm.

- For pins used on clothing or bags, keep it under 5cm to avoid being too heavy or cumbersome.

- Irregular shapes are also welcome.

Tip: Always indicate the actual pin badge size clearly on your design file

Design File & Format for Custom Lapel Pins

To ensure precise production of custom metal pins, use vector graphic software such as Adobe Illustrator (.ai) or CorelDRAW (.cdr).

If you're unfamiliar with the software, we offer artwork assistance (a small fee applies based on complexity).

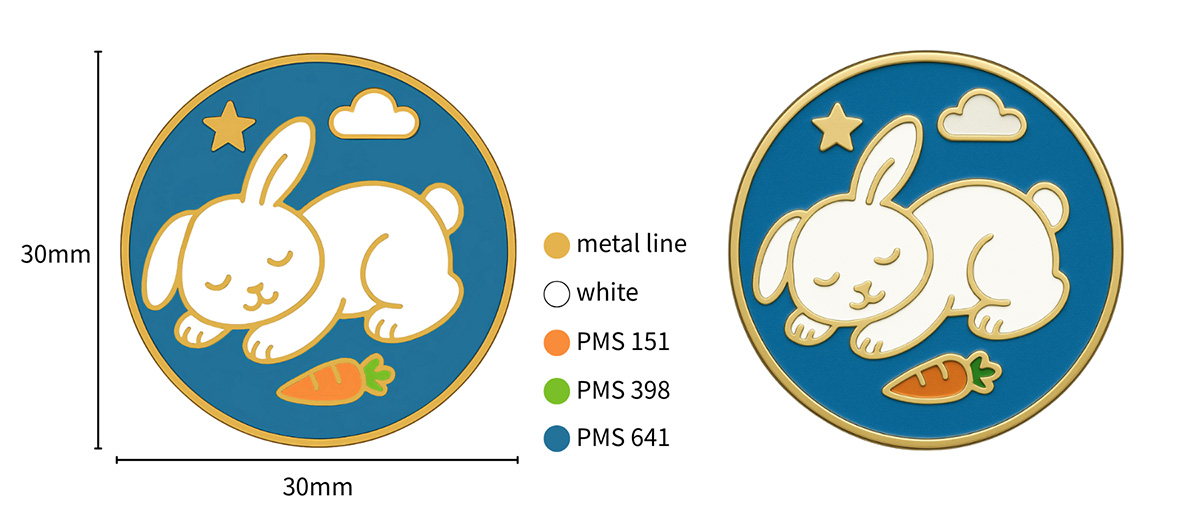

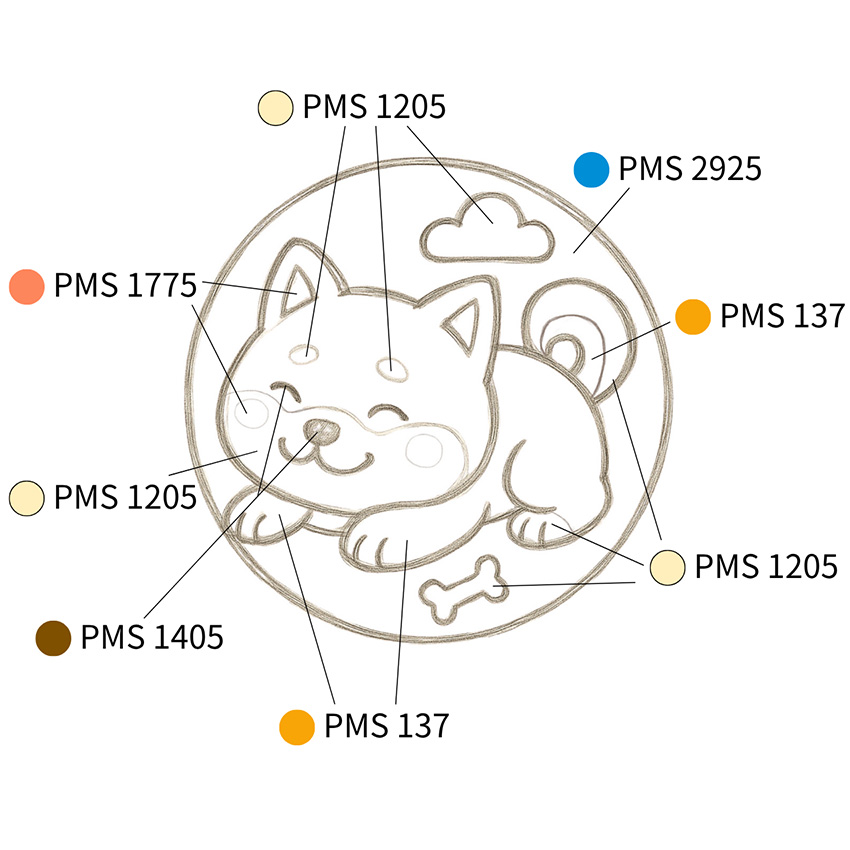

Your design file should include:

- Actual size clearly marked

- Color references based on Pantone PMS codes

- Clean separation of lines and color blocks

- Reference images (mockups or past works) if necessary to help the factory understand your creative ideas

Hand-drawn sketches are acceptable! Just make sure lines are clear, sizes are labeled, and color instructions are provided as much as possible.

Hand drawn sketch

Hand drawn sketch with PMS color

Sketch into artwork

Finished enamel pin

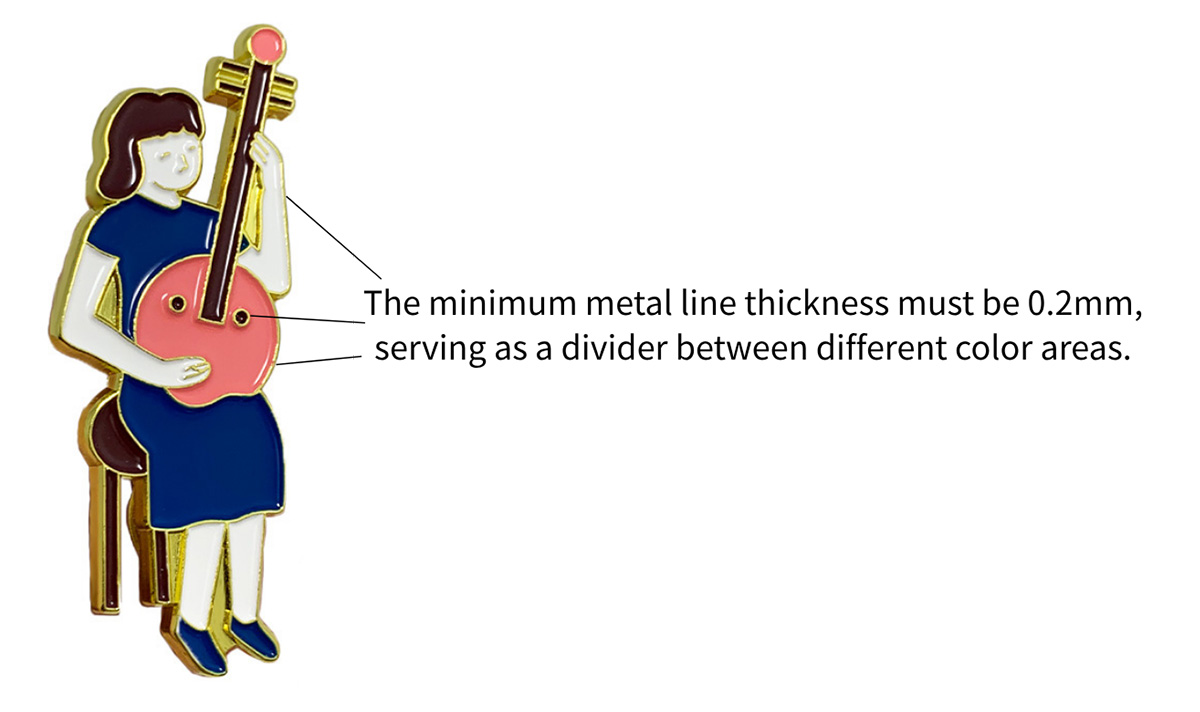

Minimum Metal Line Thickness for Custom Enamel Pin Designs

Most metal pins (e.g., soft enamel pins, imitation hard enamel pins) are created by stamping a mold and manually filling colors. Therefore:

- Each color block must be separated by a metal line to prevent color bleeding.

- The minimum metal line thickness is 0.2mm.

Using bolder lines improves visual clarity, durability, and overall finish quality.

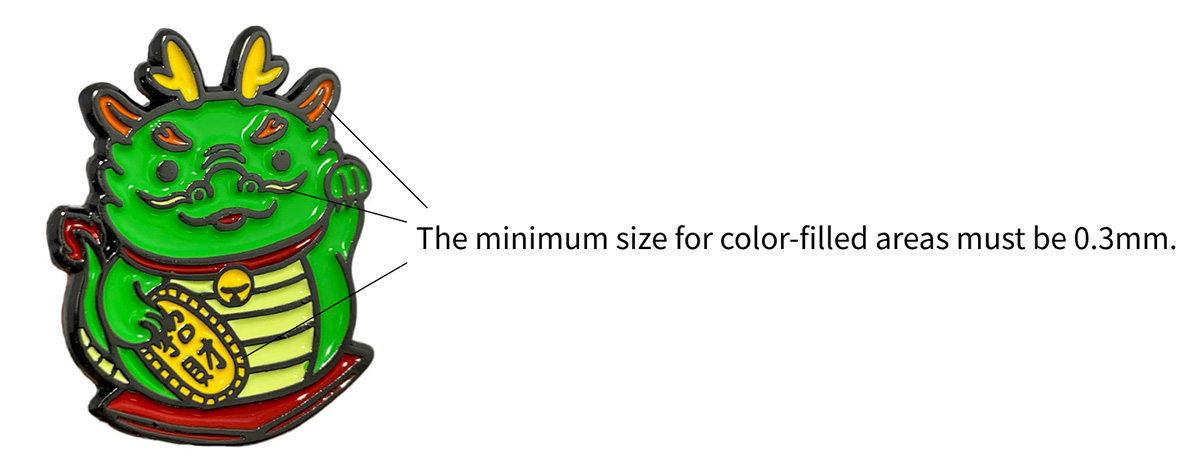

Minimum Fill Area for Colors in Custom Metal Pins

Colors are manually or mechanically filled into each enclosed area of custom metal pins. If the space is too small, color application becomes difficult.

- Minimum fillable color area width: 0.3mm

- Avoid overly intricate small grids or sharp corners, these may cause uneven filling or peeling.

Each color area must be fully enclosed by metal lines; otherwise, use a printed technique for non-enclosed areas.

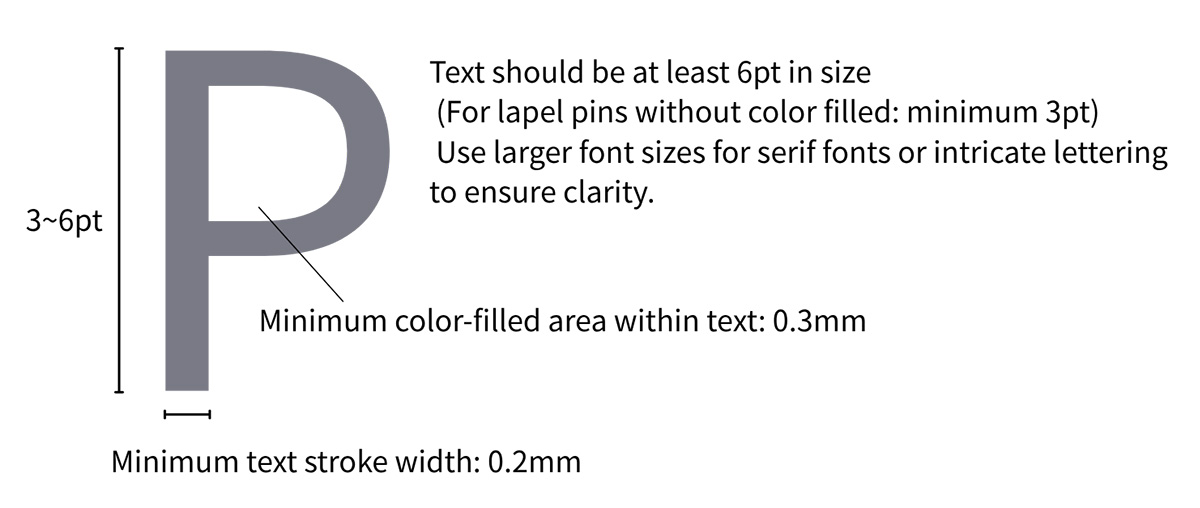

Text Size & Font Tips for Custom Made Pins

If the text of your custom made pin is too small or the font too delicate, it may get distorted or lost during mold creation.

- Recommended font sizes:

- Imitation hard Enamel pins and soft enamel pins: at least 6pt

- Lapel pins without color filled: minimum 3pt

- For serif fonts (e.g., Times New Roman), increase font size for better clarity

- All text stroke should be at least 0.2mm, and color-filled areas inside letters should be at least 0.3mm

Convert all text to outlines in your art files to avoid font errors during production.

Cutout Design Guidelines for Custom Pin Badge

Some lapel pins feature hollow designs such as holes or cutouts. These require attention to structural integrity:

- For 1–2mm thick lapel pins, the minimum inner hole size is 1.5mm

- For 3mm thickness pins, cutout areas must exceed 2.5mm

- Avoid placing holes near delicate parts of the design to prevent warping or failure during mold stamping

Our exports can provide detailed advice to help optimize cutout areas without compromising structural stability.

Summary & Tips for Custom Lapel Pins

These design guidelines for custom lapel pins are standard practices but may vary depending on the craft style (enamel, printing, without color), material thickness, and metal pin structure.

Before production, our experienced molding professionals will review your design and provide mockups for your approval, ensuring the final product faithfully brings your concept to life.

If the design is too intricate, we may suggest simplifications or alternative methods such as printing.

Explore more in our feature article: 8 Techniques to Showcase Metal Craftsmanship of Lapel Pins

Why Choose Jin Sheu as Your Enamel Pin Manufacturer?

With over 40 years of experience in custom metal pins, coins, and corporate metal gifts, Jin Sheu offers a truly end-to-end service from design to delivery.

Whether you're a first-time designer or a seasoned brand manager, we're here to help you transform your creativity into tangible products!