Verified Material Safety and Regulatory Compliance for Global B2B Buyers

At Jin Sheu, material safety and regulatory compliance are integral parts of our manufacturing process.

We maintain comprehensive laboratory testing coverage across metal materials, surface treatments, and non-metal components to support international brands, corporate buyers, and institutional projects.

Our testing system is designed to reduce compliance risks, support customer audits, and ensure products meet applicable safety and chemical regulations in global markets.

Compliance Standards & Testing Scope

Our products are tested by independent third-party laboratories in accordance with internationally recognized standards, including:

- EN71-1 Mechanical and Physical Properties

- EN71-3 Migration of Certain Elements

- REACH SVHC and Phthalates (19P)

- Heavy Metal Content Testing

- Surface Coating and Printing Ink Safety

Testing coverage may vary depending on material type, surface finish, and customer-specific requirements.

Material Testing Coverage & Available Reports

The following lists outline the available laboratory testing reports by material category.

Specific reports can be provided upon request based on product type, material selection, and target market.

Notes:

- All testing reports are issued by independent third-party laboratories.

- Report availability may vary depending on material composition, production batch, and regulatory requirements.

- Full laboratory reports are available upon request for qualified B2B inquiries.

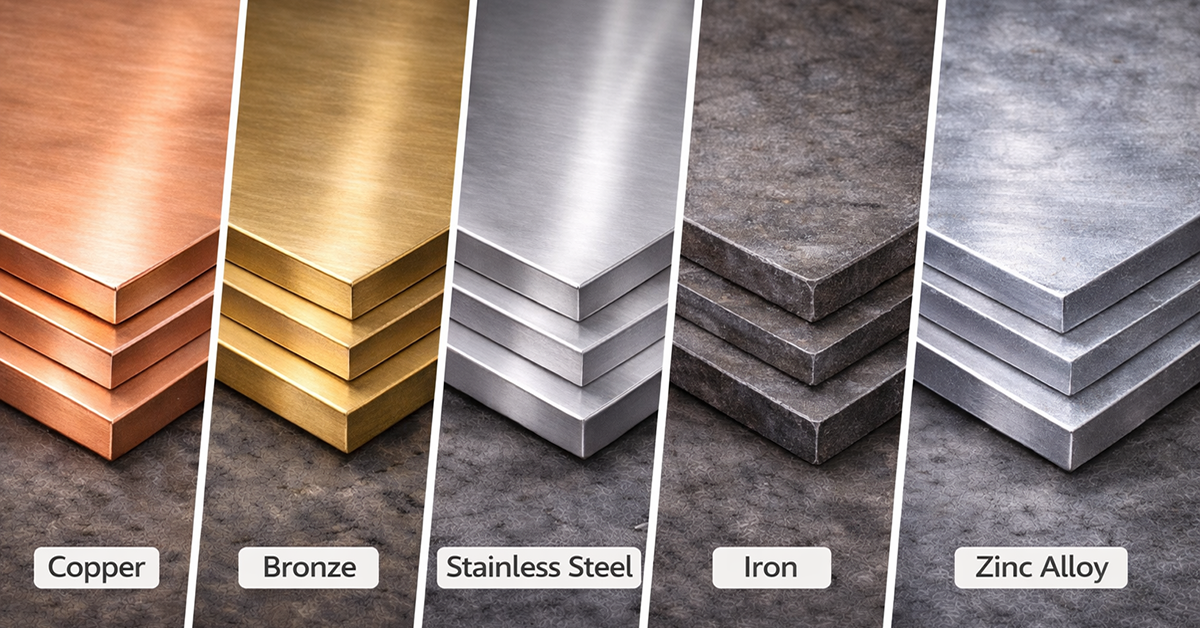

Representative metal materials commonly used in custom metal manufacturing.

Raw Material Testing Coverage

We conduct material-level testing on metal substrates used in custom metal products.

Testing scope includes heavy metal content analysis, EN71-3 element migration testing, and applicable chemical compliance screening such as CPSIA or REACH, depending on material type and target market.

This ensures that base materials used in production meet relevant safety and chemical requirements.

- Copper Testing Report EN71 / CPSIA

- Bronze Testing Report EN71 / CPSIA

- Stainless Steel Testing Report EN71 / CPSIA

- Iron Testing Report EN71 / CPSIA

- Zinc Alloy Testing Report EN71 / CPSIA

- Spin Cast Zinc Alloy Testing Report EN71 / CPSIA

Illustrative image showing electroplating and surface finish verification concept.

Colors, Coverings & Ink Materials

Colorants, inks, and covering materials used for surface decoration are also subject to safety and chemical compliance evaluation.

Testing may include EN71-3 migration testing and CPSIA compliance screening for printing inks, enamel mixtures, and related coating materials.

This helps ensure that decorative layers applied to metal products meet applicable regulatory requirements.

- Mixture Ink for Extra Printing EN71 / CPSIA

- Mixture Ink for Silk Printing EN71 / CPSIA

- Mixture Ink for UV Printing EN71 / CPSIA

- Mixture of Soft Cloisonné EN71 / CPSIA

- Mixture of Soft Enamel EN71 / CPSIA

- Transparent Soft Cloisonné EN71 / CPSIA

Illustrative representation of non-metal components and auxiliary material layers for compliance reference.

Plating & Soldering Materials

Surface treatments, electroplating finishes, and soldering-related materials are evaluated as part of our material compliance process.

Testing scope may include chemical safety screening for plating colors, solder powder, and solder oil, based on product design and market requirements.

This helps verify that surface finishes and assembly materials comply with relevant safety standards.

- 15 Different Colors of Plating EN71 / CPSIA

- Solder Powder and Solder Oil CPSIA

Representative attachment and accessory components used in custom metal products.

Attachment & Accessory Components

Attachment components and auxiliary accessories used in metal products are included within our material testing scope.

Testing may cover metal and non-metal attachment parts, such as pins, clutches, and rubber components, with applicable EN71 and CPSIA compliance screening.

This ensures that accessory parts meet safety and chemical requirements consistent with the overall product design.

- Brass Spur Nail & Brass Butterfly Clutch with Nickel EN71 / CPSIA

- TPR Rubber Butterfly Clutch EN71 / CPSIA

Quality & Compliance Management

Material testing reports are maintained as part of our ongoing quality and compliance management system.

Reports are updated based on material selection, production process, and regulatory requirements for different markets.

Specific test reports may vary by material composition, surface treatment, and production batch.

Access to Laboratory Testing Reports

Due to confidentiality and material-specific conditions, full laboratory testing reports are not publicly available.

Full laboratory reports are available upon request for qualified B2B inquiries.

Our team will review your inquiry and provide relevant documentation based on your product category, target market, and compliance requirements. Specific reports may vary depending on material, surface treatment, and production batch.

Why Compliance Matters for B2B Buyers

- Supports internal compliance reviews and audits

- Reduces regulatory and import risks

- Ensures material transparency and product safety

- Facilitates smoother cooperation with international brands

Jin Sheu is committed to responsible manufacturing and long-term partnerships built on transparency and compliance.

Ready to discuss your compliance requirements?

Contact our team to learn how our testing coverage can support your custom metal product projects.