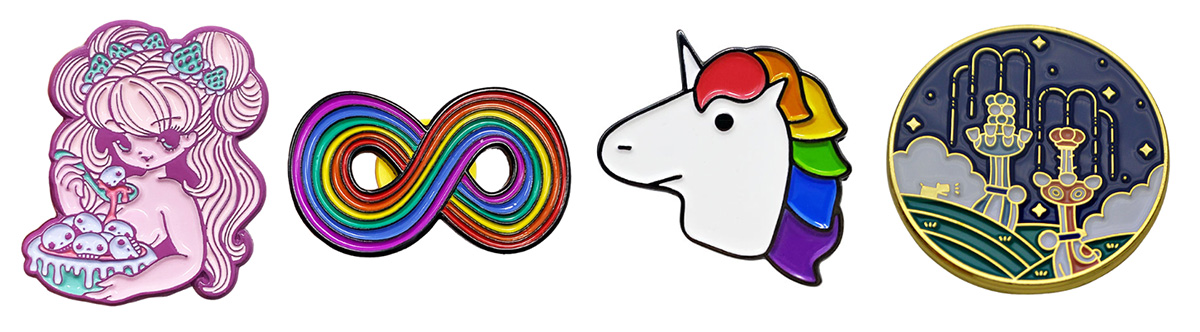

Jin Sheu creates your exclusive dream pin badge souvenirs!

With nearly 40 years of manufacturing expertise, we specialize in producing a wide range of metal products, including custom lapel pins, badges, keychains, medals, and more.

When showcasing the artistry of metal lapel pins and badges, we’re the team you can trust!

1. Screen Printing

Printed lapel pins can be categorized into offset printing (full-color) and screen printing , depending on the artwork provided by the customer.

Screen printing allows for precise PMS color matching; however, the more PMS colors required, the more expensive the printing setup fee, while offset printing does not have this issue. The printing process involves printing on a full sheet, cutting the pins to shape, and then applying a protective epoxy coating. Customers can choose whether to retain a metal border or opt for a borderless

2. Offset Printing

Offset printing uses CMYK ink blending, which does not support PMS color matching. It is ideal for designs with gradients, watercolor illustrations, or intricate artwork styles. The printing setup fee will be 4 units or a maximum of 5 units, depending on whether the design has a metal border or not.

The production process involves full-sheet printing, cutting to shape, and applying an epoxy coating. The base materials are typically stainless steel and brass; aluminum can also be used but is not the preferred material for the majority.

Customers can choose whether to retain a metal border or opt for a borderless design.

3. UV Printing

In addition to offset printing (full-color) and screen printing , UV printing is an excellent choice for 3D embossed pin badges. While silkscreen and offset printing can be applied to 2D flat surfaces only, UV printing surpasses this boundary.

UV printing also uses CMYK ink blending and does not support PMS color matching. The biggest advantage of using UV printing is its fast production speed. It can mimic the effect of soft enamel while also achieving complex or multiple colorings that traditional enamel color fill cannot accomplish. Customers can decide whether to include a white ink layer based on their desired effect.

4. Soft Enamel without Epoxy Coating

Soft enamel pin badges are available in several types: etched brass soft enamel, stamped brass soft enamel, and stamped iron soft enamel.

Pricing: Stamped brass > Etched brass enamel > Stamped iron enamel

It can be challenging to distinguish between stamped and etched brass soft enamel pin badges since both use brass. However, iron pin badges can be identified with a magnet.

The standard material is 0.8mm brass, but thicker options (up to 2mm) are available at an additional cost.

Soft enamel colors are based on PMS color codes, and popular plating options include gold, silver, bronze,copper, antique gold, antique silver, and antique copper.

Our soft enamel pigments comply with the U.S. CPSIA (Consumer Product Safety Improvement Act) standards for low lead content.

5. Soft Enamel with Epoxy Coating

The production process and material options remain the same with soft enamel pins, offering a layer of epoxy coating on the surface, creating a smooth and glossy finish for a polished look.

6. Stamped Pin Badges Without Color

Stamped pin badges without color are produced using the same process as soft enamel pin badges but without applying any colors.

The materials used are brass, or iron. Popular plating options include gold, silver, bronze, copper, antique gold, antique silver, and antique copper.

Since there are no added colors, for glossy plating (e.g., bright gold or bright silver), it is recommended to add sandblasting or matte coating to recessed areas to enhance the visibility of text and details.

7. Imitation Hard Enamel

Imitation hard enamel is durable, colorful, and has a polished, high-quality look. Its finish closely resembles hard enamel, which is why it is commonly called imitation hard enamel. It became popular in the 1990s.

Compared to hard enamel, imitation hard enamel offers faster production speeds, a broader range of color options, greater design flexibility, and a more affordable price. In recent years, it has almost entirely replaced hard enamel, even for Olympic lapel pins.

Imitation hard enamel colors are based on PMS color codes, and plating options include gold, silver, bronze, red copper, antique gold, antique silver, and antique copper (a total of 13 plating choices).

Our imitation enamel products comply with the U.S. CPSIA (Consumer Product Safety Improvement Act) standards for low lead content.

8. Hard Enamel Pin Badges (Cloisonné)

Hard enamel uses finely ground mineral powders, often imported from Japan or the UK, resulting in a limited color palette.

This is the most traditional lapel pin-making material, known for its labor-intensive and time-consuming production process, as well as its high cost. However, its colors remain vibrant and unchanged for decades, making it the ultimate material for commemorative badges.

Due to its high price, long production time, and limited color options, hard enamel has gradually been replaced by more economical and efficient materials such as imitation hard enamel and painted lapel pins.

Despite this, hard enamel remains unparalleled in terms of its historical value and longevity as a collectible material.

We believe every commemorative lapel pin carries its unique value and meaning.

At Jin Sheu, we bring your designs to life, collaborating with you every step of the way to refine the details for mass production.

We are dedicated to understanding and fulfilling your needs with exceptional service and meticulous craftsmanship. With our expertise, we are confident in creating something truly beautiful for you!